I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Thank you for Subscribing to Electrical Business Review Weekly Brief

Wire and cable manufacturing requires industry partnerships and efficient data management for quality control.

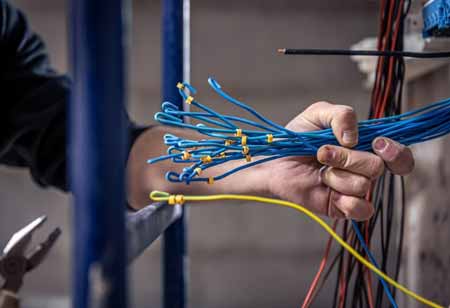

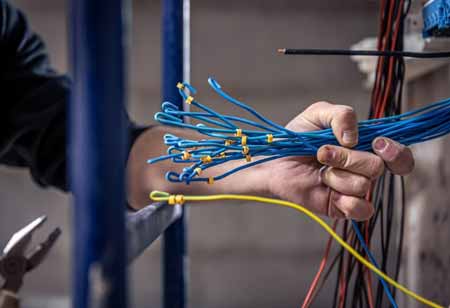

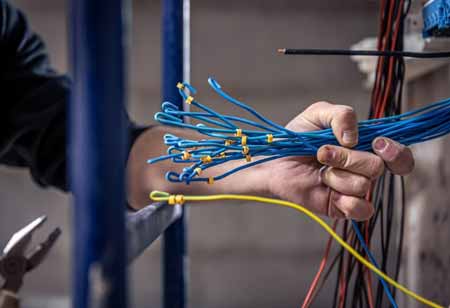

In today's rapidly evolving technological landscape, the wire and cable manufacturing industry often operates quietly in the background despite being a fundamental component of modern society. From powering homes with electricity to enabling global communication networks, wire and cable play a pivotal role in connecting the world. Wire and cable factories are intricate and multifaceted manufacturing environments where numerous factors come into play. These facilities typically produce a wide range of cable products, each tailored to specific applications. Whether it's electrical wiring for buildings, data cables for telecommunications, or specialized cables for industrial machinery, wire and cable manufacturers must meet diverse demands. Cables in manufacturing must adhere to various national and international standards, particularly when destined for global markets. These standards define specific parameters such as dimensions, weight, conductivity, length, and optical performance. Meeting these parameters within cost constraints is essential to achieving target profit margins. As the demand for customized cable solutions grows, the complexity of manufacturing processes increases. This results in multiple opportunities for errors, waste, inefficiencies, and delays. Manufacturing managers, supervisors, and technical specialists from various supporting functions often collaborate to solve these issues and ensure that business objectives are met. The wire and cable sector faces several pressing challenges impacting its ability to meet market demands. Supply chain disruptions have become increasingly common, often due to factors like natural disasters, geopolitical events, and logistical issues. These disruptions can lead to delays in obtaining essential raw materials and components, affecting production schedules and customer satisfaction. Additionally, finding qualified workers in the manufacturing sector can be a significant challenge. The demand for skilled employees in the wire and cable sector remains high, and the scarcity of qualified candidates further exacerbates the situation. Innovation, competitiveness, and meeting market needs require a skilled workforce. To remain competitive and innovative, companies in the wire and cable sector must have a forward-thinking approach. This entails focusing on the future, fostering innovation, and ensuring sustainability. However, addressing these challenges requires more than educational institutions alone can provide. The industry needs partnerships with educational institutions and government support to build a strong and capable workforce. Initiatives to fund STEM (Science, Technology, Engineering, and Mathematics) programs and enhance their appeal to students at a young age are critical. Industry partnerships offer financial, technical, and educational resources that educational institutions may lack. Support for STEM initiatives fosters an environment that encourages students to pursue careers in related fields. By starting young, students receive the support and resources necessary to make informed decisions about their future careers. Partnerships have long been the cornerstone of successful programs and initiatives at the associate or technical degree level. Community colleges, in particular, heavily rely on guidance and investment from local industry partners. These partnerships help refine the focus of educational programs and improve their ability to prepare workers effectively. Industry collaborations provide valuable feedback, enabling educational institutions to identify the skills in demand in their specific region. By tailoring their programs to match these requirements, colleges can better equip students for success in the workforce. Moreover, industry partners may offer access to critical resources, including equipment and funding, to help colleges achieve their educational goals.